3D Printing Transforms an Historic Train Station to Its Former Glory

Ford Motor Company just reopened the Michigan Central Station in Detroit after an extensive six-year renovation that involved its additive manufacturing engineers, who went from 3D printing auto part prototypes to 3D printing architectural accent pieces. The new Station opened to wide acclaim for its authentic and faithful resurrection of the building's unique character.

Ford embarked on the preservation project after acquiring the abandoned train station in 2018 to be the centerpiece of Michigan Central, a 30-acre technology and cultural hub in Detroit's Corktown neighborhood. Michigan Central will bring Ford employees together with external partners, entrepreneurs, students, and even competitors to co-create new products, services, and technologies.

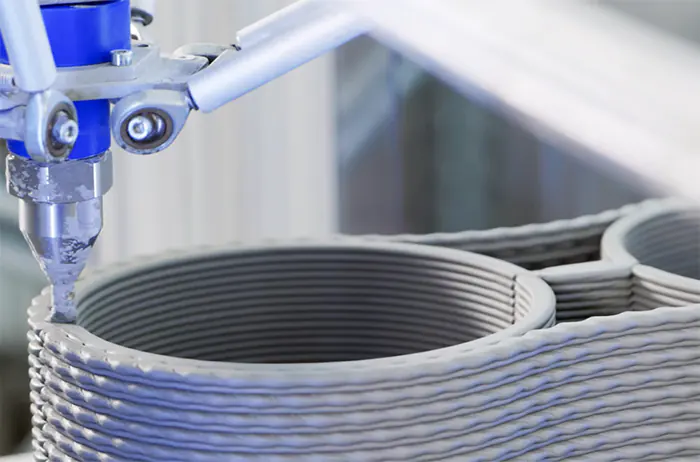

For the restoration, nearly 3,000 skilled tradespeople were hired to cut stone and carve wood, but for some elements of the project, the traditional methods were a lost art. Ford turned to newer technologies, namely 3D printing and 3D scanning, that could reproduce ornate elements with the same precision, but faster and more efficiently.

Originally designed by architects Warren & Wetmore and Reed & Stem, the same team behind New York's famed Grand Central, Michigan Central Station first opened its doors in 1913 as one of the country's most spectacular transportation terminals.

It saw 4,000 daily passengers at its peak, but, following decades of declining rail travel, was shuttered in 1988 and sat vacant for three decades, experiencing severe neglect, weathering, decay and vandalism.

To recreate some of the intricate architectural details, such as rosettes and filigree on the building's large arch windows, several teams at Ford, including Research and Advanced Engineering, Manufacturing Technology Development, and others – were tapped for their expertise in 3D computer-aided design processing, 3D scanning, and 3D printing techniques.

The teams were able to 3D scan parts of the building and reverse engineer them in order to restore each one to their original designs. Different scans were combined and missing pieces redesigned when necessary. Ford's manufacturing technology team printed the rosettes and filigree using a lightweight polymer that made for easier installation.

Nearly 550 pieces were 3D printed, with 20 variants of differing lengths and flower positioning. These pieces mark Ford's first use of polymer additive manufacturing for architectural construction, and highlight the company's innovative spirit and dedication to maintaining the building's rich heritage.

Audrey Chen is a female interior designer who received her BFA from The Art Institute of Atlanta. She is skilled in creating functional and aesthetically pleasing spaces that reflect the needs and personalities of her clients.