Buying a 3D printer - What you should consider

3D printers have become surprisingly affordable and can be a huge help in more ways than you think. With a 3D printer, you can easily replace small components from household appliances and devices that may be unavailable to you otherwise. Everything from action figure repairs to artwork is possible with the right 3D printer. There are a variety of 3D printers available that have a range of features and use different types of materials, so it's important to understand your options to find the best device for your needs. In this 3D printer buying guide, we'll walk you through the most important factors to consider when shopping for a 3D printer.

What Do You Need to Print?

Just like with any piece of technology, knowing what you plan to use your 3D printer for will go a long way in helping you make the right purchase. The strength, smoothness, and overall quality of the final printed products are determined by the type of printer and materials used in making them. If you plan to use the printer as a hobby, budget filament-based devices may be perfect. Or, perhaps, you need the 3D printer for your business to replace machine parts or create objects that will see daily use. In that case, a more expensive resin or powder material printer may be necessary. There are hundreds if not thousands of uses for 3D printers, so make sure to consider all your possible creations before making a purchase.

Types of 3D Printers

The two most common types of entry-level 3D printers are SLA and FDM. These devices are fundamentally different in how they operate and the materials they use. Thus, knowing the differences between them is essential when considering buying a 3D printer.

There are also many other types of 3D printers available on the market today—but they are often reserved for manufacturing or other industrial applications. Below, you will find some information on the most common types of 3D printers:

FDM Printers

Fused Deposition Modeling (FDM) printers function by using heat to melt filament and feed it through a tube to create various shapes. Objects are created by adding materials on the X, Y, and Z-axis. FDM printers are relatively standard for hobby 3D printing and typically come in two types of frame construction: Cartesian and Delta.

- Cartesian printers have dedicated motors for the X and Z-axis while the bed moves along the Y-axis to speed up print times. Most FDM printers are Cartesian.

- Delta-style printers have a separate motor for each axis, resulting in longer print times and sloppier final products.

- Keep in mind that all FDM printers have the drawback of creating coarse final prints that require manual smoothing to finish.

SLA Printers

Stereolithography (SLA) printers use a chemical treatment process known as photo-solidification to form the different layers of the final print product from liquid resin. An ultraviolet laser hardens the desired print pattern into the material one layer of resin at a time. These printers are capable of some of the highest quality prints with incredible detail. Unlike FDM, the final products from SLA printers are smooth and require little post-print work.

SLS Printers

Selective Laser Sintering (SLS) printers work similar to SLA but use a laser and powder materials to create 3D objects. The laser points at specified areas within the powder, which hardens, creating detailed yet sturdy final products.

SLS printers are common for printing machine parts or objects that need to be durable yet complex and intricate. SLS printing materials can be rather hard to come by, however, so SLA printers tend to be more favored.

DLP Printers

Digital Light Processing (DLP) printers are also similar to SLA printers, with one significant difference. While SLA printers use ultraviolet light, DLP printers use more conventional light sources, like an arc lamp. DLP is the oldest form of 3D printing but is still considered high-quality by today's standards. That said, they are somewhat rare in availability and often steep in cost, so DLP printers do not see much use in the consumer market.

SLM Printers

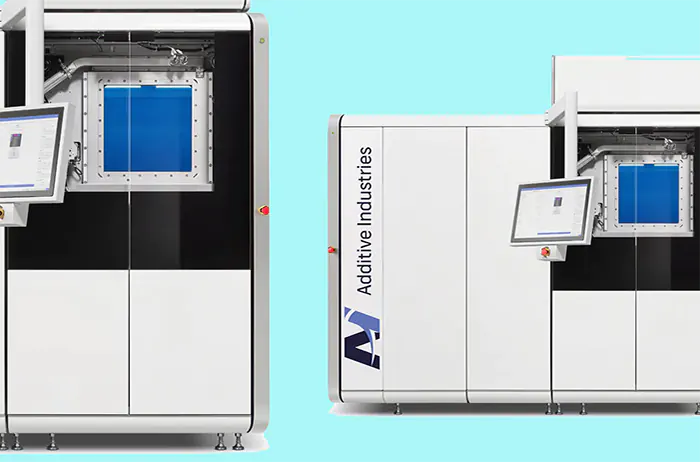

Selective Laser Melting (SLM) printers use a high-powered laser beam to form 3D objects out of powdered metals. These printers are not typically found in homes but are rather commonplace in universities and the medical field. SLM printers are ideal for creating machine parts with complex geometry that must be both incredibly thin and detailed.

Understanding 3D Printing Materials

Now that you know the basic types of 3D printers available, another important point of consideration is the materials you will be using to print with. Some materials only work with certain types of devices, and each material has its pros and cons. Here's what you need to know:

Filament

FDM printers use plastic filaments to print objects layer by layer. Different material types can have significant effects on the final printed product. Filament materials come in many different variations that can have specific use cases. There are, however, two plastic print materials that are far more common than others:

- ABS (Acrylonitrile Butadiene Styrene). A common and inexpensive material that is great for small kitchen objects and other basic items. ABS plastic is standard in toys and consumer manufacturing. Beginners can benefit from the affordability and ready availability of ABS print materials.

- PLA (Polylactic Acid). Compared to other materials, PLA is an environmentally friendly solution. PLA is great for many uses but is most common in food storage and disposable items. For everyday use, PLA can get expensive and is a bit harder to find than ABS.

Resin

Unlike filament materials, resin print materials are a bit more abstract. Different manufacturers can have other names for their specific resins, but there are typically three resin quality categories to be aware of:

- Standard: Often transparent, the most basic type of resin materials are affordable yet still durable and an excellent solution for users needing to print sturdy objects frequently—the drawback being the quality and clarity of the finished product. Lower-grade resins can sometimes look cloudy or obscure in color.

- High-Grade: You start to see all of the specialized names and brands of resin with the high-grade materials. High-grade resins can have specific colors that make them more desirable for particular tasks. These same high-quality resins can be significantly more durable than their affordable standard resin counterparts. The major problem with high-grade resin is cost, which can quickly raise with print volume.

- Medical-Grade: Not often found in home or hobbyist printing, medical-grade resins are reserved for the highest quality of print jobs. This material is used primarily in the medical field, as the name would imply. However, the incredible durability and complexity of these materials have practical uses in other professional applications. By far, medical-grade resins are the most expensive of 3D printer materials.

3D Printer Specifications

When buying a 3D printer, there are a few specifications that matter more than others. Below, you will find what each means and how they affect your 3D printing experience:

Resolution

Unlike with screens, the smaller the resolution of a 3D printer, the better quality of the finished product. The three dimensions of printing can make the quantifying of resolution somewhat intricate and confusing. However, all you need to remember is the lower, the better.

Speed

When it comes to printing, being fast is not always the most desirable trait. Often, 3D printers with high print speeds sacrifice quality to get to the final product faster. Slower devices take so much time because they are capable of creating much more complex final prints. No matter what you are printing, it will take a substantial amount of time, so it is worth it to get a slower device with better final print quality.

Supported Materials

Knowing what types of materials you can use in your specific 3D printer is crucial in determining the regular costs of using the device. Some materials such as powders for SLM printers can be scarce in availability and steep in price. Knowing how often you plan to print and the type of objects you intend to create can help you determine which types of materials you should use in your 3D printer.

Print Capacity

This can also be referred to as the build area. This specification tells you the maximum size of printable objects for your device. This is important to consider, because larger printers quickly rice in base price and cost of printing materials.

Keep in mind that smaller printers can also print some items in parts that can later be assembled into a larger object. Hence, a massive build area is not always needed. Conversely, sometimes a single large part may need to be printed for use in a professional setting. In that case, a 3D printer with a large print capacity is a must.

Summary

3D printers have quickly become commonplace at work and home. From small toys to machine parts, 3D printers can create impressive objects from a wide variety of materials. Buying a 3D printer can be a daunting task due to the many types of devices and complicated printing methods. The best place to start is to decide what you are going to print and how often you will be printing it. These factors are crucial in finding the best machine for you and can go a long way in understanding the many different specifications of 3D printers. Remember, no matter what choice you make, getting a 3D printer has many benefits, and this guide is available to help you find the best machine at any time!

Casey Osler is a highly-skilled interior designer and product designer with a passion for creating beautiful, functional spaces. With a Master's degree in Interior Architecture and Product Design from Kansas State University, Casey has the education and experience needed to bring any design project to life.