Choosing the best 3D Printer for Your Needs

What should I know before buying a 3D printer?

So, you've decided to get a 3D printer or fleet of 3D printers. There's just one problem: you have no idea where to start. Buying a 3D printer isn't as easy as buying a regular printer that makes 3D objects.

There's plenty to know before you can find the right printer for your needs. In order to help you get the right information, here are some of the basics you need to know:

- 3D Printer Types: There are three main types of 3D printers, Fusion Deposition Modeling (FDM), Stereolithography and Stereo Laser Sintering (SLS).

- 3D Printing Materials: 3D printers utilize Poly Lactic Acid (PLA), Polyvinyl Alcohol (PVA) and Acrylonitrile Butadiene Styrene (ABS). These three have benefits and drawbacks, and depending on what you're printing will influence which you're using. ABS is good for objects that connect to one another, like LEGOs, whereas PVA is good for objects that need to dissolve from water contact, such as fishing bait containers. PLA is environmental friendly material.

- Printing an Object: In order to print a 3D object you need a stereolithography (STL) file, which transmits the specs to the printer needed to create your object. You can make these files yourself with a computer-aided design (CAD) software, or download a blueprint. From there, you put the file through slicing software, which is literally telling your printer how to slice your object.

- Getting Good Quality: Printers need both speed and resolution in order to get an object of good quality. The better the resolution of a printer, the more detailed it will be able to create the object. The speed of a printer will also impact quality – too fast and the finer details may be lost in printing. 3D printing takes a long time, and is not for the impatient. Intricate and high-detailed objects benefit from a high-resolution printer that prints slowly and purposefully.

This is only a small scratch on the surface of everything there is to know about 3D printing. However, by having a basic understanding of these four concepts, you'll be able to quickly build upon them and grow your knowledge of 3D printer choices.

What is the best 3D printer for beginners?

There are two ways to discuss the best 3D printers for beginners: recommending actual 3D printers for beginners or discussing what to look for in a beginner 3D printer. We have some recommendations on 3D printers at the bottom of this article already, so we'll aim to address the latter.

The first thing for beginners should be the kit they choose. 3D printers can be pre-assembled, semi-assembled, or completely makeshift. Think of this as building a computer: you can get everything you need in one box, buy some pre-built products and mix-and-match the rest, or buy every single piece of hardware separate. In the case of a beginner you'll probably want everything out of the box, so look for something that requires minimal assembly or additional product purchases.

Next up, you'll want to consider the material you're using. This isn't about the ease of use since the printer is doing the work, but consider the quality of the object instead. Beginners will likely want something easy to work with and durable when printed. For that reason, PLA is a very good material for beginners. You won't get much shrinkage or warping from PLA. Now, if you're a beginner using something that might experience high stress or will demand more resistance to wear, ABS is the way to go. So, while “it depends on what you're printing” isn't always a clear answer, beginners will need to consider what they want to print in order to determine what material will be best.

If you need some product recommendations on 3D printers, check the bottom of this article. We've included some good beginner 3D printers for you to check out alongside the more complex and dynamic options.

What are the advantages of owning a 3D printer?

This is a great question to ask yourself or your organization. What advantages of 3D printing are there, and why bring one in house?

The answers, ultimately, can be focused by individual industry or objective. A science department at a university will get a far different usage out of their 3D printer than a small business looking to make product prototypes to show investors or clients.

While we can't provide every single advantage to every single industry and use case, we can give you some broad advantages for owning a 3D printer.

- Lower Costs: For those who are looking to build models for educational purposes, create displays or build prototypes, 3D printing allows you to do this at a much lower cost because you'll be using your own materials and equipment.

- Faster Development: In addition to those lower costs, you will also be creating these designs at a much faster rate. If you're a medical teacher looking to show a 3D model of the heart, you can print one out in a few hours rather than order one and wait for it to be delivered.

- Prototyping: This is for those who create their own products to sell. You can now prototype products and see how they look quickly, rather than wait for each new prototype to arrive after ordering it.

- Manufacturing Efficiency: On a large scale you can use 3D printing to increase your own manufacturing efforts and make the process much more efficient. You can streamline components or full products and get them out the door and into the hands of your customers faster and with greater cost control.

What are the pros and cons of 3D printing?

We've already highlighted some many benefits to 3D printing, but we'll mention a few more here that we haven't mentioned already. 3D printing is more than 10 times faster and five times cheaper than other methods, allowing you to build prototypes and other objects in hours rather than days. In addition, 3D printers are often one-tenth of the price of more sophisticated rapid prototyping machines. The printers are small, safe, reliable and easy-to-use, which is why they are becoming more and more popular in areas outside of manufacturing.

There are a few cons to using 3D printers, however. Compared to high-end rapid prototyping machines, the finish of your objects won't always have the same quality and texture that a finished product. It might feel rougher or less sturdy than a full prototype, so while 3D printing is good to build a few different prototypes you may find your quality lacking in achieving the quality you're seeking.

Speaking of quality, materials also come into play. We've touched on some of the materials used in 3D printing already, but they can be limiting, from actual materials to colors available. Lower-end devices will produce lower quality objects, so if you want better results, it will cost you a lot more money.

You also have to consider that bringing these operations in-house means they exist in-house. If something breaks down, or materials aren't printing correctly, that will be on your organization to invest. You'll likely want to bring people on board who can oversee 3D printing operations for these reasons, more so if you're using them for manufacturing reasons.

Other types of 3D printing materials

We've highlighted some common and key materials for 3D printing. But you're not limited to just those we mentioned. Of particular interest, 3D printers can print with a variety of materials, such as:

- Plastics / Resin

- Metals

- Ceramics

- Carbon Fiber

- Food products (such as chocolate)

The best questions to ask for choosing a beginner 3D printer

Sometimes the pure fun of something makes it all worthwhile. Find the best beginner 3D printer to entertain your family or kick off a new hobby for yourself. Here are some key questions to ask yourself when you are looking for the best beginner 3D printer.

- What is my budget for a 3D printer? - You can find 3D printers for beginners at a variety of price points. Consider whether your 3D printer is likely to be a mere hobby or if you'll ultimately use it for business ventures as well.

- How important is a "plug-and-play" 3D printer? Even the very best 3D printer models likely still require some degree of customization and configuration to arrive at a usable device. However, if you like to tinker, you might enjoy a more hands-on, DIY 3D printer kit where you can build your own device or a semi-assembled 3D printer that requires less tinkering. Of course, you can also choose the fully assembled printer as well.

- What materials must the printer be able to support? Knowing ahead of time what materials you need your printer to handle can help to ensure you choose the right 3D printer. Chat with a knowledgeable technology pro to help steer you in the right direction in finding the best beginner 3D printer.

- What features are most important? A great 3D printer may not have every single feature you'd like, but you can certainly rank your priorities and look for the printer that has most if not all of them. Consider factors such as operation sound, cloud and WiFi connectivity and size of the printer, to name a few.

Other questions to ask yourself when choosing a 3D printer

Choosing a 3D printer that's right for you means knowing what you want and need. The best way to determine this if you haven't already is to ask yourself questions about your goals. In order to help you with that process, we've identified some questions you can use to get the conversation started on what kind of 3D printer you should choose. Consider these questions when looking for the best 3D printer:

- How much can the company spend on this 3D printer? Keep a budget in mind to help guide your decision on the best commercial 3D printer.

- What materials matter most? Not all commercial 3D printers can print using the same components. Some 3D printers offer multiple choices in printing medium while others may focus more specifically on one element, such as Nylon 12, Resin, and so forth.

- What is the intended product targeted for 3D printing? Knowing as much as possible about the process and end result can help to ensure you choose the best 3D printer. Just like different small kitchen appliances specialize in certain dishes, many 3D printers offer their own specialties as well, such as functional prototypes, cases and housings, and end-user parts requiring special materials.

A deep-dive into 3D Printer types/h3>

Fused deposition modeling (FDM) is currently the most popular and readily available form of desktop 3D printing on the market. Developed and originally implemented in the 1980s, Fused deposition modeling allows you to print operational prototypes as well as ready-to-use products as such LEGO bricks, plastic gears and much more. All components printed with FDM can go in high performance and engineering-grade thermoplastic, which makes this technology useful for mechanical engineers and manufacturers.

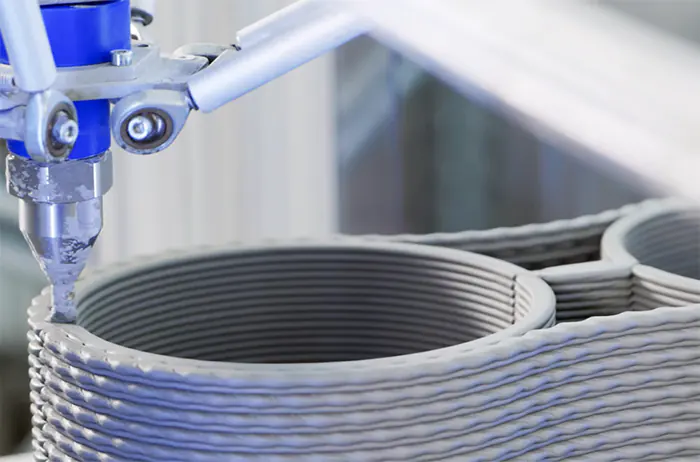

Printed pieces have excellent mechanical strength and heat resistance. FDM printers construct 3D objects layer by layer, starting at the bottom and moving upwards by heating and extruding thermoplastic filament. This form of 3D printing is useful in all fields from new product development to prototyping to end-product manufacturing.

Stereolithography (SLA) is the oldest form of 3D printing. It works by exposing a layer of photosensitive liquid resin to a UV-laser beam; the resin then hardens in the desired pattern, and the object is built layer by layer until it is complete. Objects printed by SLA 3D printers have smooth surfaces, but often the quality depends upon the printer type. Printing via SLA involves a longer process as printed objects need to be rinsed using a solvent and then put into an ultraviolet oven to complete processing.

Digital Light Processing (DLP) is the fastest of all 3D printing methods. A layer of hardened material can be printed in a few seconds and quickly transferred to allow for printing of the next year. Like SLA, DLP 3D printers use liquid plastic resin but instead of a UV-laser beam, the resin is melted with arc lamps. This light source causes the impressive printing speeds because the amount of light allows the resin to quickly harden. DLP is a robust technology that produces high resolution models every time, even allowing you to use cheaper materials for complex and detailed objects.

Selective Laser Sintering (SLS) technology builds objects layer by layer like other printing methods, but a major difference is that it uses powdered material rather than liquid resin. SLS uses a laser to form strong 3D printed objects from powdered material, which allows objects to be printed without any additional support structures. SLS is popular for printing customized goods because a large selection of materials may be used, such as nylon, glass, ceramic, aluminum, silver, steel and more.

Meet Martica White, a talented interior designer with a passion for creating beautiful, functional spaces. With a degree in Interior Design Technology from Seminole State College of Florida, Martica has the education and experience needed to bring any design project to life.